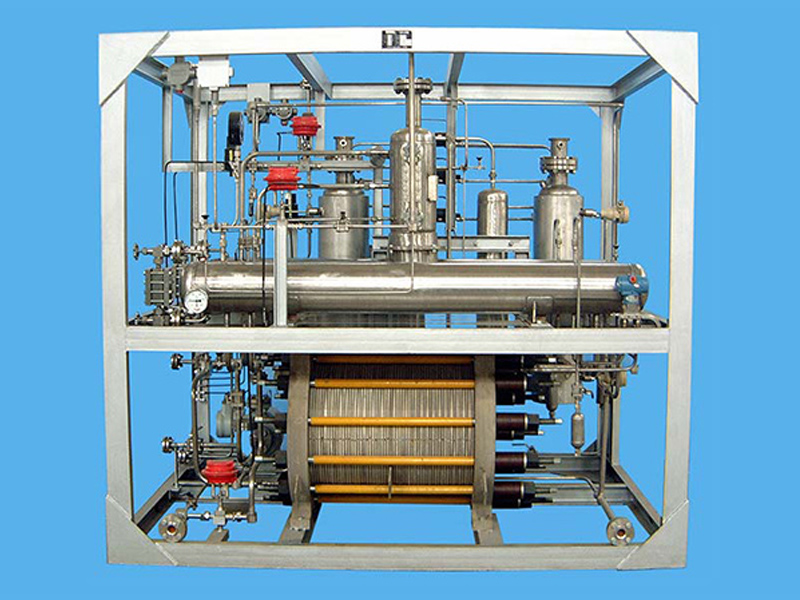

H2 Recovery Equipment

Hydrogen recovery refers to the removal of dust, oil, oxygen, and water from the hydrogen discharged in the industrial production process, so that the quality of the hydrogen can meet the production requirements again, and the system is collectively referred to as the secondary recycling.

The recovery process is to use different technologies according to the contamination impurities and their contents, normally use catalytic reaction and molecular sieves adsorption to purify the hydrogen to the required purity.

The hydrogen recovery equipment applies to the hydrogen recovery, purification and recycling in the reduction furnace (e.g.: processing of tungsten and molybdenum powder), annealing furnace (e.g.: bell-type furnace), zinc plating process and hydrogen protection process in metallurgical industry.

Parameter for reference:

Capacity: 100 ~ 10000Nm3/h

Dew Point: ≤ -70°C adjustable according to requirement)

Oxygen Content: ≤ 5ppm

Working Pressure: ≤ 0.039MPa, Air Pressure Adjustable

Drying and Regeneration Mode: Regeneration of Product Gas, No Hydrogen Loss

Power Consumption of Full Load: ≤ 0.1KW/m3H2

Control Mode: PLC Automatic Control

Note: above pictures and parameter are only for reference, please contact for detail of H2 recovery device.